Pinhole Detection

Home / Our Solutions / Packaging Inspection / Pore Detection

■PATERA FOCON Foil

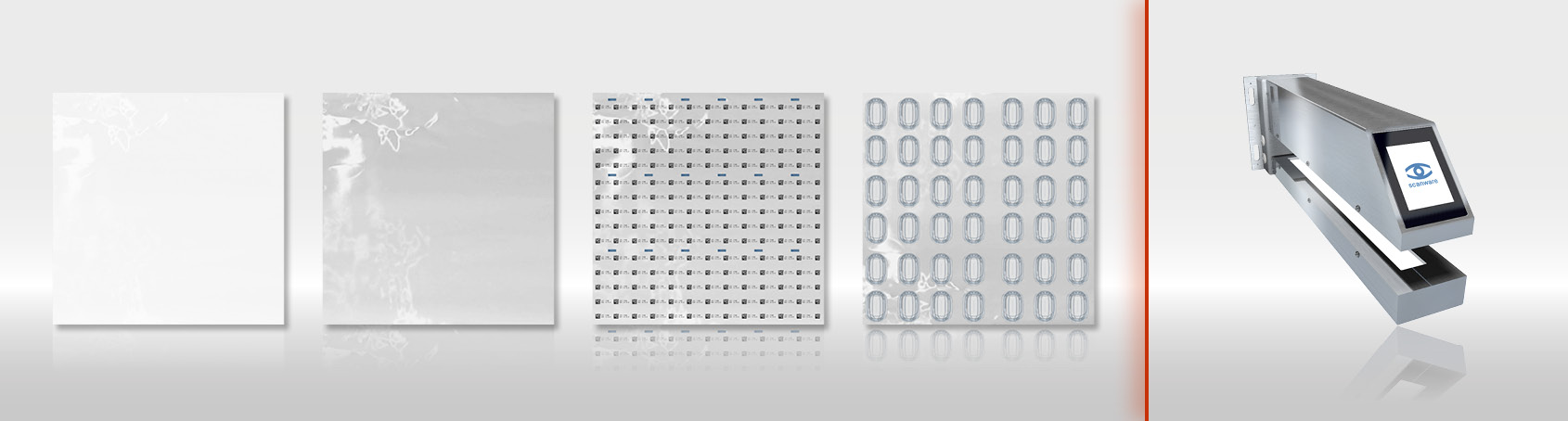

The optoelectronic inspection system detects pores and micro-fissures in aluminium foils up to one metre wide. It is installed across the running direction of the foil lane, usually between the forming and filling stations.

If pores are detected, the system gives a signal so that filling is suppressed and ejection takes place.

The Pinhole Detection Unit enables the producer and contract packager to increase productivity, is easy to install, robust, fail-safe and keeps pace with high belt speeds.

■Application Areas of the Pinhole Detection Unit

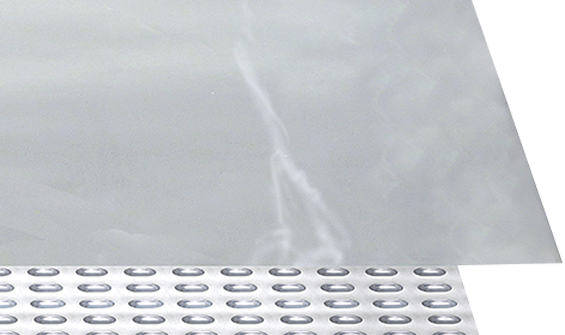

Detection of micro-cracks in aluminium bottom foil (flat or formed)

Detection of micro-cracks in aluminium sealing foil

For use without a guideway, an adapted mechanism can be supplied to minimise disturbing light irradiation from the outside. This also allows the use on bag machines.

■Advantages of Foil Inspection

- The system can easily be integrated onto any new or existing blister and sachet machinery

- Large, easily readable touch screen displays current mode of operation and evaluations in the selected language

- The detection sensitivity is adjusted electronically down to 25, 50, 100, 250 and 500 μm

- Access control in accordance with GMP regulations prevents unauthorised changing of format parameters

- Thanks to its modular build, PATERA FOCON Foil can be provided in foil widths of 200 – 1,600 mm, in steps of 50 mm

Then please use our contact form. We will get back to you as soon as possible.

■Functions of the PATERA FOCON Pinhole Detection

Depending on the conditions on the packaging machine, one or two zones can be set for detection. The detection area is divided into two zones along the centre line of the foil lane. This enables a more differentiated separation of defective and perfect blisters.

At the same time, production waste caused by tears and pores is minimised. With FOCON, a considerable reduction in waste can be achieved.

With an integrated shift register, FOCON works independently of the packaging machine. This performs defect tracking and is easily programmed by the operator.

Related inspection tasks

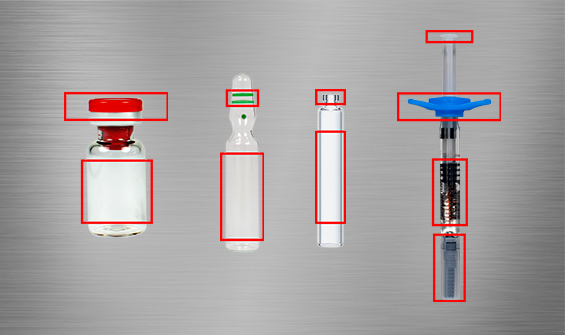

Shaped aluminium blisters can be inspected for correct shape using the three-dimensional inspection. The use of the laser-based system with a high-resolution line-scan camera and triangulation algorithm allows false colour or elevation imaging of the blister cups. This means that misshaped blisters can be detected before or after filling – productivity can be improved even further.

■Sustainability

Use of the pinhole detection unit enables suppression of filling of the product to be packaged. This reduces wastage and

saves ressources. Furthermore, the system now is fl exible in setting the detection senstivity electronically, so a single

unit can be used for all possible detection sensitivities.

Further to that, by utilising the system alongside other scanware systems on the line, the productivity can be increased

even more. For example, statistical evaluation, but also upgradability and the high quality of components enable longevity

of the systems and a fast Return On Investment.