Colour Inspection

Home / Our Solutions / Blister Inspection / Colour Inspection

■SPECTRA CL Colour Product Inspection

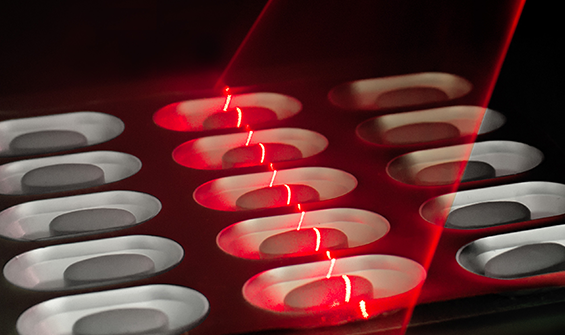

The SPECTRA CL blister inspection is used to detect cross-contamination, size, position, fragments and overfilling of products on packaging machines. It is the ideal solution for standard inspection tasks in colour. Correctness of the different colours by means of RGB values is displayed in real time – making safety in the packaging process child’s play.

■Inspection Criteria and Objects

Inspection objects:

- Tablets

- Oblongs

- Sugar-coated tablets

- Hard and soft gelatine capsules

Examination criteria:

- Colour

- Presence

- Size

- Shape

- Circumference

- Position

- Fragments

- Overfilling

- Serial errors

■Advantages of scanware Colour Recognition

Due to the use of the real-time operating system QNX®, the Colour Product Inspection SPECTRA CL offers outstanding speed and reliability. All parameters in the colour detection can be applied simultaneously – without loss of function.

The comprehensive analysis options, user-friendly software that can be tailored to your needs and the automatic learning run make it particularly easy to use. In addition, the system can be upgraded at any time to high-resolution system SPECTRA HR to reliably detect not only correct colour but also the most demanding product-film combinations, for example contraceptives.

Then please use our contact form. We will get back to you as soon as possible.

■Software Facts of Colour Detection

The result on the line is something to be proud of – production and format documentation as well as analysis of lane and cup filling offer you unique opportunities to detect errors in the infeed and reduce ejection. This is made possible by visualisation on the software interface.

The image memory works with up to 50 images, based on which an individual system suggestion for parameter limits is automatically created. This offers greater safety and simpler operation than standard limits to be adjusted by the user.

The automatic learning run enables a fast transition to production, as object position, blister geometry and product colour are automatically recognised. Of course, a manual learning run is also possible.

Automatic mask tracking compensates for trigger differences on intermittent machines.

The comprehensive audit trail and global parameter limits for extra high safety are fully 21 CFR Part 11 compliant.

The electronic illumination regulation is set in 16 illumination levels by means of a simple measuring line. This allows the optimum contrast to be achieved for inspection of colour values; the format-related settings allow high flexibility on the line.

■Technical Data - Hardware

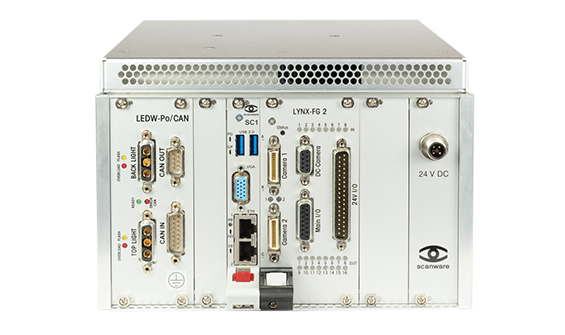

Evaluation unit

- 42 HP, 3,5 RU

- 240 GB SSD hard disk

- scanware-developed frame grabber

Illumination

- Developed by scanware, with up to 3,000 LEDs per standardised unit

- Toplight, backlight, side light or diffuse light – can be combined freely

- Homogeneous, reproducible and adjustable in 16 brightness levels for optimal detection of colour differences in the sensor and the software

- Colour disks in red, green or blue for optimising illumination conditions

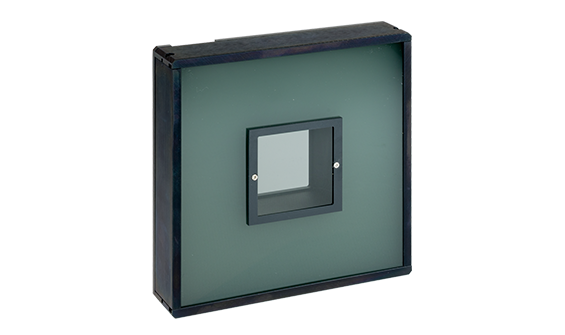

Camera

- High-speed CMOS camera

- Camera Link interface for low-interference data exchange of large

amounts of data and thus longer cable lengths than USB and FireWire - Evaluation speed: 35fps

- Camera resolution: 2, 5 or 12 megapixels

- Colour resolution in 256,000 greyscales

- RGB-Bayer filter: Calculation of colour values according to brightness using filters in red, green and blue

- Powerful, non-condensing device tailored for excellent results in continuous use

- Integrated colour correction which is further enhanced by the software algorithms developed by scanware