3D Inspection

Home / Our Solutions / Blister Inspection / 3D Inspection

■SPECTRA 3D

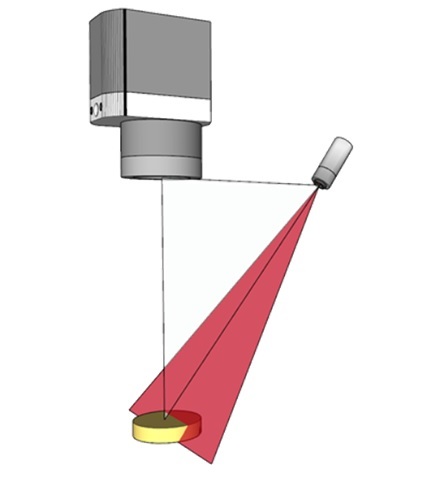

The high-resolution, laser-based SPECTRA 3D image processing system is used to check the geometry of the film and product for undesirable deformations of any kind, such as pressure marks, bulges or chipping. Thus, it offers unique security for product inspection in the pharmaceutical packaging industry. Thanks to the use of the real-time operating system QNX, the camera system works with the highest speed and safety. The combination of high-quality hardware and sophisticated software means that the three-dimensional blister inspection offers producers of sophisticated products inspection possibilities like no other.

Functionality

The geometry of the objects to be inspected is illuminated by a laser. The resulting image is captured by a high-resolution 3D line scan camera. The camera image is then processed and digitised. Then the digital signal is processed and evaluated.

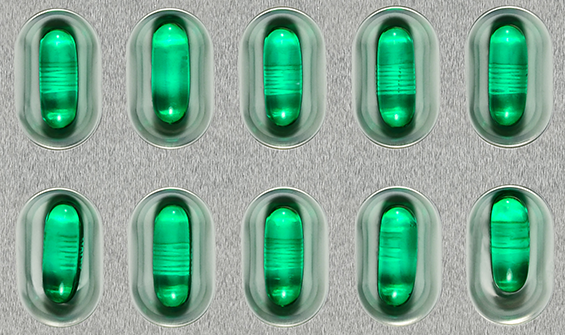

■Inspection Criteria and Objects

Inspection objects:

- Tablets

- Oblongs

- Hard and soft gelatine capsules

- Powder

- Aluminium pockets

- Plastic capsules after filling

- Multi-layered tablets

Examination criteria:

- Presence

- Size

- Form

- Circumference

- Position

- Fragment

- Overfill

- Consecutive errors

- Height

- Volume

■Advantages of 3D Product & Blister Inspection

Since both the geometry and the volume of the product are detected, the method offers significant advantages over two-dimensional inspection. SPECTRA 3D enables the safe inspection of inspection tasks where colour control alone does not provide the necessary safety. These include double fillings stacked and next to each other, fragments under and next to the product, split multi-layer tablets, powders in very small quantities as well as all inspection tasks with very low contrast such as grey products in an aluminium blister.

The 3D inspection can already be combined with other scanware inspection systems of the latest generation on one platform and controlled via a common terminal. This provides clarity and saves space on the line. In addition, in many cases it is possible to retrofit the system with options (hardware and software). It is also possible to combine the system with SPECTRA HR to also inspect colour.

Then please use our contact form. We will get back to you as soon as possible.

■Software Facts of the 3D Inspection Solution

The SPECTRA 3D software includes numerous highlights such as the display of format parameters and documentation. Reference and defect images are analysed and product-related tolerances are set. Mask management is also controlled by the operator.

The colour display of the evaluation expresses the elevations. Low-lying objects are expressed in red tones, higher objects in blue.

3D representation of the evaluation. This can be rotated as desired using arrows to achieve the optimal view.

When evaluating powder cups, the volume calculation is greatly improved by adapting the algorithm for solids. Further information on this special application can be found here.

■Further Applications

Height detection with SPECTRA 3D can also be used for Braille recognition, inspection of ampoules and inspection of folding box webs.

■Technical data - Hardware

Evaluation unit

- 42 HP, 3.5 RU

- 240 GB SSD hard disk

- scanware-developed frame grabber

- Image multiplexer for up to 15 cameras

Laser technology

- Laser class 1 (normal operation)

- Wavelength 660 nm

- Beam angle 30°

For more information on laser safety, please see our information brochure.

Camera 3D

- Camera type: 3D line scan camera

- Camera interface: GigE

- Camera resolution: 1,536 pixels per line

- Objects per image: 224

- Format memory: >1,000

- Number of cameras: 1-3

- Evaluation speed in images per minute: 900 (at 1000 lines)

- Height resolution: 0.1 mm 128 greyscales height