Inspection on Convex Surfaces

Home / Our Solutions / Code Inspection / 1DC Tube Inspection

■SIGNUM 1DC Tube Inspection

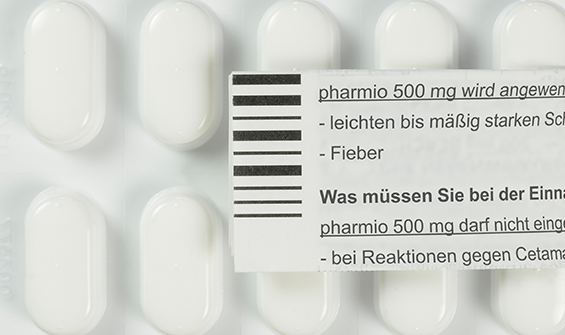

The code inspection for convex surfaces SIGNUM 1DC is installed between tube infeed and tube filling. The system checks printed one-dimensional codes, both single and multi-coloured, as well as print marks on aluminium and plastic tubes. This prevents tubes with incorrect printing from being filled in the first place and increases productivity on the line.

■Inspection criteria and objects

Testable objects:

- Aluminium tubes

- Plastic tubes

Test criteria

- Pharmacode

- Miniature Pharmacode

- Printing marks

■Advantages of 1DC tube inspection

- Integration into the newest QI visualisation

- Visualisation of the current reading and a history of the 15 previous results

- Ideal add-on to existing packaging lines

- Good and bad signals are evaluated using signals in the integrated shift register

- Extraordinarily high speed and reaction time after the reading

With pleasure we arrange an appointment with you for a personal discussion.

■Facts of the 1DC tube inspection solution

The inspection of codes on tube is carried out by SIGNUM 1DC . Pharmacodes, minipharmacodes and print marks printed on tubes are checked.

Software

Pharmacodes, minipharmacodes and print marks can be read by making the appropriate settings in the menu selection, which is designed to be particularly user-friendly and is linked to the latest QI software architecture.

The reading result is transmitted in real time to the machine control. The reading of printed pharmaceutical codes can be carried out with this code reader at positions where a camera solution is not possible.

Distortions of the code, which can occur due to the curvature of the tube, are compensated for by the software.

The required installation space of the sensor is extremely small compared to camera solutions and thus enables a high degree of flexibility. In addition, integration into the IMPERA data management system is possible.

Design

Thanks to the compact design, the system can be implemented on all common types and model types of any tube filler and is therefore an optimal add-on solution for any production line.

The 1D code inspection is equipped with code readers that achieve an exceptionally high reading speed and response time, as well as providing trouble-free evaluation and reliable inspection.