Software

Home / Our Solutions / Components / Software

■In-house developed software for strong performance

The quality of the systems is scanware’s top priority. In order to be able to guarantee this, the development of the software and the selection and development of the hardware go hand in hand. scanware equips packaging machines along the entire line; in doing so, operation always remains simple and user-friendly thanks to the uniform menu.

■User-friendly operating concept

All scanware systems are operated by a uniform menu structure. This enables the user to operate each system intuitively. The menu has a self-explanatory structure – the operator does not need any previous knowledge but can start working after a short briefing. Operation via the TFT screen offers the operator maximum comfort. The large keys on the virtual keyboard allow the necessary data to be entered quickly.

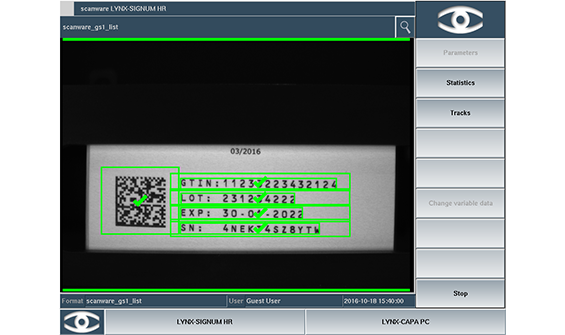

■Automatic teach-in run

The automation of the teach-in process simplifies the teach-in and thus enables a quick transition to production. The object position, blister geometry and product colour, as well as the position and rotation of codes, are automatically recognised. A manual teach-in run is also possible.

■Highest security thanks to real-time operating system

By using the hard real-time operating system QNX®, system failures are greatly minimised. The operating system is often used in life-support systems and in the aerospace industry and consequently offers the highest level of safety. Data exchange takes place within milliseconds and no UPS is required. In addition, the risk of viruses is very low.

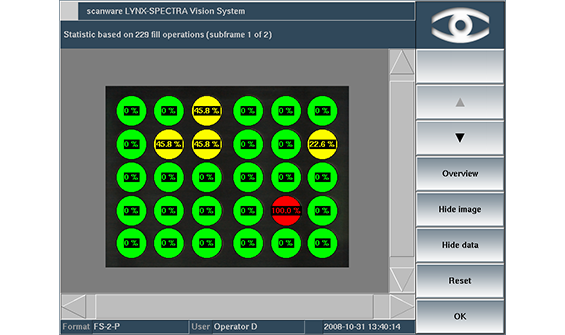

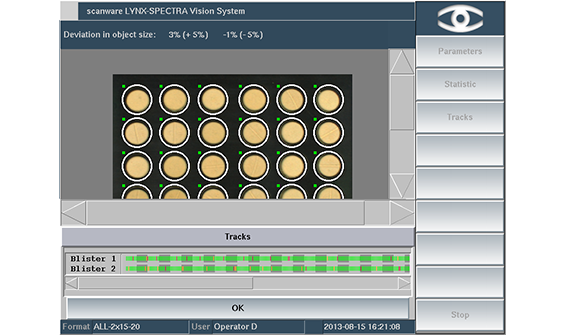

■Detailed evaluation statistics

Umfangreiche statistische Funktionen erlauben es dem Produzenten, die

Produktion zu optimieren und den Auswurf zu senken. Hierzu gehören die spur- und napfbezogene Füllstatistik, Bahnenansicht, die Erkennung von Klebebandfarbe sowie die automatische Maskennachführung, die Unregelmäßigkeiten beim Folientransport ausgleicht.

■Diagnose deluxe für Auswerteoptimierung

The error diagnosis shows the operator exactly on the basis of which criterion the object is faulty. Furthermore, it is possible to relearn criteria such as product size and colour in order to optimise the evaluation. Depending on the software package, a defect image memory can be created and format tests can be carried out.

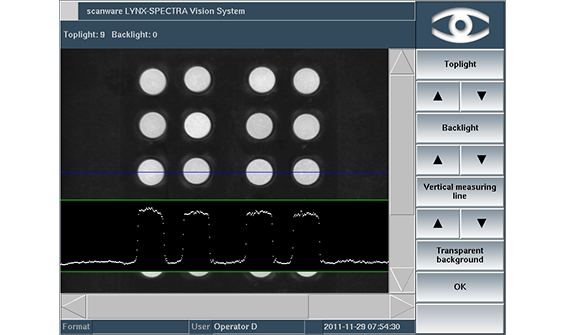

■Optimum illumination setting

The setting of the illumination is guided by the software. The settings can be saved format-related. Project-specific, the inspection of each object in two brightness levels at the same time is also possible.

Then please use our contact form. We will get back to you as soon as possible.