Quality Assurance

Home / Our Service / Quality Assurance

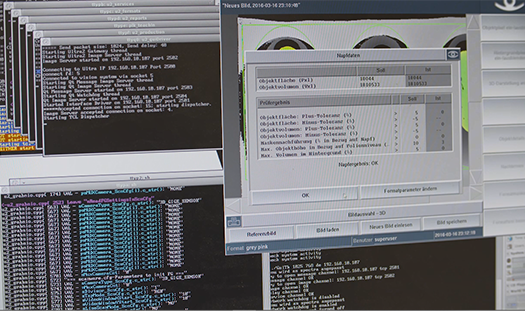

■Quality management system

The quality management system of scanware electronic GmbH has been certified annually since 2000 according to the DIN EN ISO 9001 standard and applies to all areas. It sets itself the main goal of meeting customer needs and increasing customer satisfaction.

All development phases are worked out, defined and the development progress is inspected regularly. If necessary, they are adjusted to ensure that the quality and deadline requirements agreed with customers or set by the company are met.

■Mistake culture

At scanware we work with an open error management system. This means that we deal with errors transparently so that together as a team we achieve the goal of error prevention and quality assurance.

In doing so, we systematically evaluate the errors and initiate countermeasures to avoid errors and error consequences.

■Qualification and validation

The validation of the systems according to GAMP, GMP and 21 CFR Part 11 can be carried out by the technical customer service. It is carried out under normal operating conditions according to predefined test plans. If there are different intended applications of the products, multiple validations can be carried out. At the customer’s request, additional validation can be carried out during commissioning at the customer’s site.

Standard or project-specific installation and operation qualification documents provide the solid basis for this.

■System stress tests for robust hardware

Just about every product is affected by climatic influences such as temperature and humidity and is thus influenced in terms of suitability for use and service life.

To guarantee the reliability and robustness of all the hardware components we use, we inspect every single component under the expected and possible requirements in our climate test room.

Then please use our contact form. We will get back to you as soon as possible.

Cem Daş, Repairs:

“Quality is the be-all and end-all of scanware. Our customers know that we can repair even a 20-year-old device. Since we put all components through their paces, the systems run for that long.

But if I find a fault, I go one step further. With development, we then find a way to solve the problem for all future projects. Once a customer came to our office and brought me a defective system. After his lunch break he could take it back repaired and in the evening the line was running again! So you can see – quality is visible.”