Black & White Inspection

Home / Our Solutions / Blister Inspection / Black & white Inspection

■SPECTRA BW Black & White Product Inspection

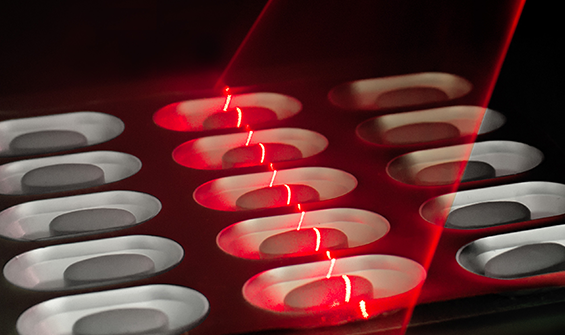

The monochrome product inspection SPECTRA BW verifies a number of product-specific criteria of pharmaceutical products – for example presence, position, area and shape as well as overfilling and broken pieces. The black-and-white system is a cost-effective solution for production lines in the pharmaceutical industry where cross-contamination can be ruled out due to technical conditions, such as on mono lines. Software and hardware can be upgraded to colour blister inspection at any time for colour detection.

■Inspection Criteria and Objects

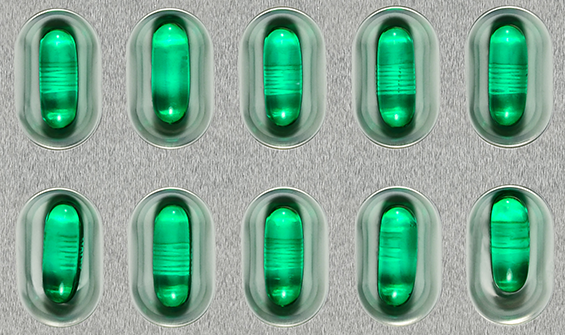

Inspection objects:

- Tablets

- Oblongs

- Dragees

- Hard and soft gelatine capsules

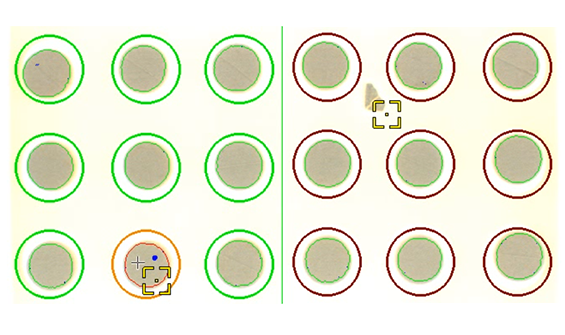

Examination criteria:

- Presence

- Size

- Form

- Circumference

- Position

- Fragments

- Overfilling

■Advantages of scanware Black and White Inspection

The system offers outstanding speed and excellent statistical analysis tools. All parameters used in the system can be applied simultaneously without impacting speed. If the requirements on site change, the system can be upgraded to the Colour Product Inspection SPECTRA CL at any time.

The black and white inspection can be used for a number of alternative inspection tasks and offers the user much more than a standard application.

Bottle Inspection

During the forming of plastic bottles, the black & white system inspects the correct edges at the bottle opening and the seam at the bottom of the bottle. The flexible mould is cut off at both ends. Several cameras are used to inspect the cut edges before filling.

Pouch Position Inspection

When filling pouches with powder, contamination and improperly sealed pouches occur due to slanted positions. Here, the transfer of incorrect pouches into the distribution chain can be prevented by using SPECTRA BW. The camera inspects the position of the pouch during filling and triggers an ejection as soon as the placement of the pouch shows an excessive angle.

Refill Inspection

With monolines, ejection can be reduced by means of a refill station. The Black & White Product Inspection SPECTRA BW provides pocket-specific data so that empty pockets can be filled specifically before the blister reaches the sealing station.

Then please use our contact form. We will get back to you as soon as possible.

■Software Facts of the Black & White Blister Inspection

The classic of our blister inspections offers a range of software features that increase both ease of use and safety. Here the user is guided in a targeted manner. The basic structure is the same for all scanware systems so that no new training is required when changing systems. Outstanding software functions, such as:

- Configurable

- Machine stops in case of overfilling, position error, serial error, etc.

- Partial teach-in runs for product size and greyscale

- Comprehensive audit trail

The teach-in run offers automatic parameter determination. Based on the images and defect images taken, the system calculates a concrete suggestion that the user can adjust as required.

The adaptation of the illumination to the product and film is done by a simple measuring line. The values determined are stored in the format and are thus always reproducible.

The running production statistics offer an evaluation of both the number of ejected products and the reason for ejection and its frequency. In addition, the visualisation of the previous results enables the quick detection of serial errors.

■Technical Data - Hardware

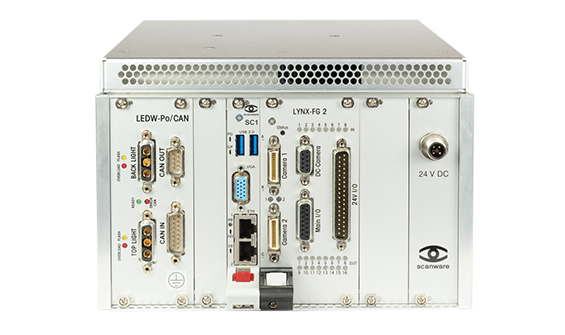

Evaluation unit

- 42 HP, 3.5 RU

- 240 GB SSD hard disk

- scanware-developed frame grabber

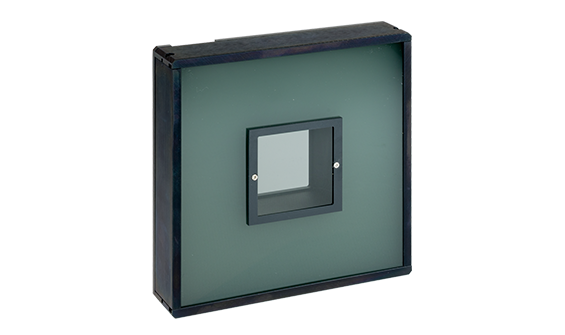

Illumination

- Developed by scanware, with up to 3,000 LEDs per standardised unit

- Incident light, transmitted light, side light or scattered light (diffuse) – freely combinable

- Homogeneous, reproducible and adjustable in 16 brightness levels for optimal detection of colour differences in the sensor and the software

- Colour disks in red, green or blue for optimising the illumination conditions

Camera

- High-speed CMOS camera

- Camera Link interface for low-interference data exchange of large amounts of data and thus longer cable lengths than USB and FireWire

- Evaluation speed: 35fps

- Camera resolution: 2, 5 or 12 megapixels

- Colour resolution in 256 greyscales