Packaging Inspection

The inspection of primary packaging, such as parenterals and foil, is subject to a variety of tests and controls to ensure the quality of products.

Home / Our Solutions / Packaging Inspection

Packaging Inspection

scanware is an expert for 100% inspection in the packaging process along the entire line. In addition to the visual inspection of products and code as well as track & trace, primary packaging is also inspected. Here the inspection expert offers two comprehensive solutions for your packaging line in the area of primary packaging.

■Types / components of packaging inspection

In order to inspect packaging, scanware starts at two points: Inspection of the packaging material and the presence of packaged products in the blister.

The multifaceted talent for parenterals

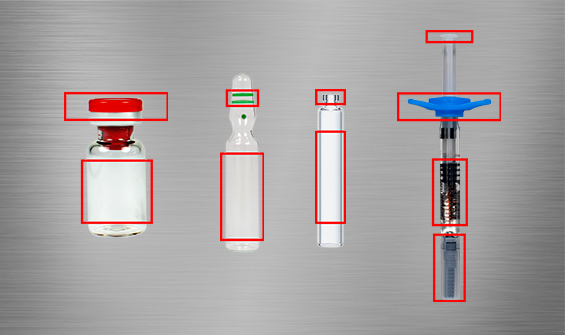

PATERA Parenterals inspects preparations that enter the body bypassing the intestinal tract. The packaging inspection system is extremely versatile and is used on packaging and labelling machines to automatically eject defective products and to exclude the possibility of admixture with foreign products. The image processing system inspects objects such as ampoules, vials, syringes and carpules for a wide variety of examination criteria. It was designed with artificial intelligence-based vision technology.

Ampoules – Here, the number, sequence and quality of the colour rings as well as the presence of the label are inspected.

Vials – Visual inspection of the presence and colour of the cap and the presence of the label.

Syringes – Quality of needle cap and finger grips, condition of finger grips and plunger, distance between plunger grip to finger grips, and label presence.

Carpules – the presence and quality of the cap colour and label presence are inspected.

Full inspection of multiple, different products per blister is possible. This allows a product change to be made quickly on the line.

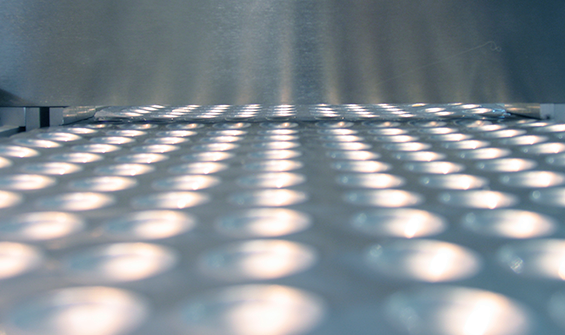

Detection of smallest pores and cracks

The PATERA FOCON foil optoelectronic inspection of foil for microcracks enables the detection of pores and cracks in aluminium foil up to 1,000 mm wide. It is installed between the mould and the filling station across the running direction of the foil lane. If pores are present, a signal is given for filling suppression and ejection. The unit can handle speeds of 1.5 m/s and thus keeps pace with all common blister machines. The system is equipped with state-of-the-art self-diagnostic functions. All outputs are short-circuit proof and designed for fail-safe operation. Bottom web can be inspected both flat and shaped. The top film can also be inspected for micro-cracks.

By using the PATERA FOCON pinhole detection, the detection range of 25 – 500 μm and, thanks to automation, the subsequent filling suppression, productivity can be increased and production waste sustainably reduced. The division of the detection area into zones also contributes to this, so that faulty and faultless blisters can be differentiated.

Then please use our contact form. We will get back to you as soon as possible.

■Advantages of the scanware product range

No matter what control task your production requires, the scanware range offers a solution for your application. The various products are based on a common operating structure and a modular design, which allows flexible installation and monitoring of your packaging process from a single source.

Across the board, the IMPERA line manager can be integrated to control the machines and components as well as implement Serialisation and Aggregation, if required. scanware’s expertise in the medical sector is second to none and its proven precision and safety are also indispensable for customers in the cosmetics and food industries. Whether it is the content in the blister, the position of a label or the machine readability of a QR code or printed image – the scanware product range offers you a reliable solution.

And together with the CURA all-round carefree package, your line will always be in optimum condition. And should you have a particularly sophisticated inspection task, scanware successfully implements specific special developments thanks to in-house software and hardware development – just contact us.

scanware – inspection system along the entire line for pharmaceuticals, cosmetics and food.