Japan Quality

Home / Our Solutions / Blister Inspection / High-Resolution Inspection / Japan Quality

■SPECTRA HR in Japan Quality

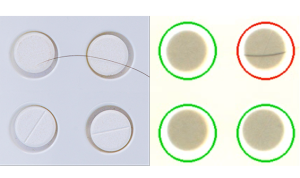

The blister inspection SPECTRA Japan Quality offers the highest image resolutions for high-speed evaluation. This makes it the optimal system for high demands such as those of the Japanese pharmaceutical market, which requires visually flawless products due to cultural conditions, as consumers perceive external minimal defects as serious reasons for rejection.

The colour system continuously distinguishes 16 million colours even in three-shift operation at high-speed. Offering the same resolution at high speed, this enables the detection of minimal flaws and tiny defects.

■Inspection Criteria and Objects

Inspection objects:

- Tablets

- Oblongs

- Dragees

- Hard and soft gelatine capsules

- Special forms

- Sealed products

Examination criteria:

Smallest contaminants such as e.g.

- Painting defects

- Particles on the tablet or lacquer

- Surface defects

Additional examination criteria:

- Colour

- Presence

- Size

- Shape

- Position

- Circumference

- Fragments

- Overfill

- Consecutive errors

■Advantages of the Japan Quality Application

Hardware and software are selected with the demands of the Japanese market in mind. Japanese goods in general are subject to very high standards of uniformity and standardisation. The consumer’s critical eye, thus sharpened, also questions the correctness of the processes and thus the product as such in the case of external flaws. Thus, the appearance of the product becomes just as decisive a criterion for producers for the Japanese market as harmlessness and efficacy.

As a result, the following characteristics become grounds for rejection:

- Paint defects

- Particles on tablet or lacquer

Critical quality defects requiring a recall:

- Contamination with hair

- Contamination with non-production particles

■Software Adaptations for Japan Quality Inspection

The software works in real-time thanks to the use of QNX®. All functions can be used simultaneously – without any loss of speed. Outstanding software functions, such as production and format documentation, comprehensive audit trail, easy-to-understand menu-guided operation.

Since even the slightest reflections are problematic during product inspections in Japan Quality, the measuring line enables reliable and reproducible adjustment of the W-LED illumination. The measurement line can also be used vertically when the camera images of several cameras are displayed

are displayed one below the other.

Camera-specific colour tolerances have a negative effect on the colour evaluation. The software feature “Colours per camera” ensures that the colour values are defined separately for each camera during teach-in in order to capture these camera-related deviations and enable accurate evaluation. The operator works comfortably on a single image.

The presence of a hair is recognised by the system as foreign colour and leads to ejection. The detection performance depends on the inspection area and resolution. A product with minimal contaminant such as paint defects or flaking is reliably detected and ejected by SPECTRA Japan Quality.

Then please use our contact form. We will get back to you as soon as possible.

■ Application-specific Hardware

In order to speed up evaluation, the scanware Frame Grabber conducts image pre-processing tasks.

Cascading multiple 3CMOS cameras is of paramount importance to achieve the necessary image resolution.

■Further Product InspectionApplications

■Post-Seal Product Inspection in Japan Quality

Inspection from below and after sealing can also be easily implemented with SPECTRA Japan Quality. The illumination is adjusted with side light and matching backlight to minimise reflections.

This successfully detects the following defects:

- Tablet powder even on the underside

- Foreign bodies on the foil

■Technical Data - Hardware

Camera

- 3 CMOS

- Camera Link interface for low-interference data exchange of large amounts of data

- Camera resolution: 3x 2, 5 or 12 Mpx

- Colour resolution in 16 million colour shades

- Installation of 2 to 6 cameras