Level 3 Connections

Home / Our Solutions / Line Management / Levels

■IMPERA

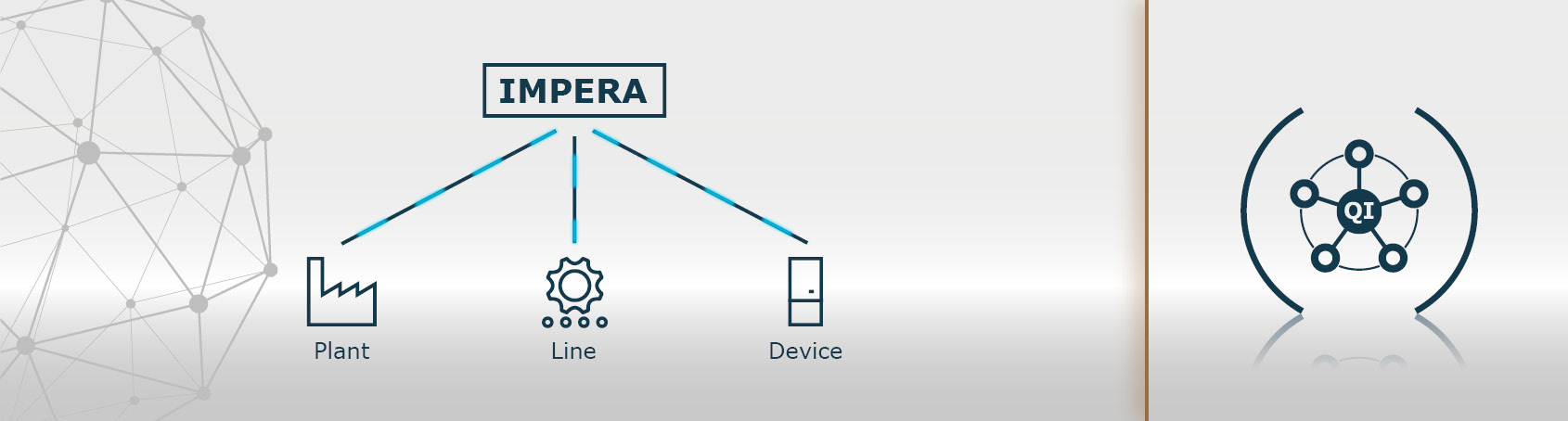

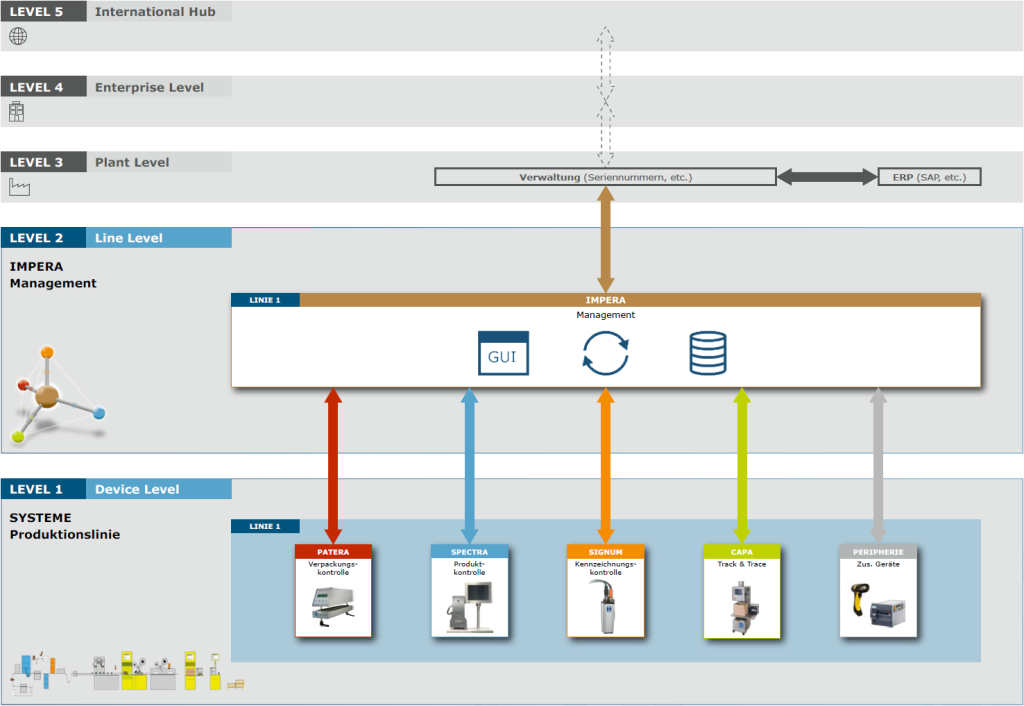

In the organisational structure of the processes at a production site or in the company, a sensible approach is a subdivision according to levels. In this way, the individual acting components on the line are considered together and the higher-level administration of the line, as well as the management of the site, are clearly subdivided.

■Line Manager as Technical Actor

Based on the ISA 95 standard, the individual levels of the packaging line are described with a hierarchy model.

Level 1 – Device Level: Includes technical equipment such as optical inspection systems, track & trace systems, barcode printers or label printers.

Level 2 – Line Level: Describes the line management system that combines all data from the Level 1 units.

Level 3 – Plant Level: Refers to the site-wide systems that ensure data exchange with various lines the management and coordination of inventory data, product serialisation, product and order data.

Level 4 – Enterprise Level: Includes global data exchange between individual locations and is responsible for a wide range of business processes

Level 5 – International Hub: Beschreibt die Verbindung zu einer übergeordneten Netzwerkebene wie z. B. einer Aufsichtsbehörde

■Advantages of the scanware level concept

- Multiple GUI can be used at the same time – so data and orders can be prepared without causing a stoppage on the line

- The layout has been simplified so that only the relevant modules are visualised

- Perfect for your line by selecting the relevant modules and GUI for your users

- Can be operated by mouse or touch

- Interface to common systems e.g. SAP, Atlantic Zeiser etc.

- Implementation of various serialisation requirements according to the market

- Combination of decentralised real-time data communication and centralised management of order data

■Level 3 Interfaces

scanware EPCIS

SAP

Arvato

Hicof

Atlantic Zeiser

Vimachem SSM

Werum

Then please use our contact form. We will get back to you as soon as possible.

■Modules of the line manager

Key modules

- Broker – Communication centre for data exchange as well as process status in real time, which other modules can retrieve

- Process handler – decentralised communication – data exchange within groups, which can take place without network access – so the network is not burdened

- Database – storage and management of all relevant data on hard disks

- Real-time interface – coordination of data exchange between modules and the database

Application modules

- Log-In Server – The module allows the passwords of all components to be managed centrally

- Aggregation – Customer-oriented mapping of the aggregation process and visualisation of the packaging process. Different points in the process each have their own modules, e.g. for bundles, shipping boxes, pallets, both for automated or manual processes.

- Rework module – functionality for de-aggregation, sample removal and return of products to the packaging process.

■Interaction and configuration modules

Variable Data Manager – Manage variable data such as expiry date, serial number, as well as country-specific formatting – labels are configured.

Report server – management of statistics and event log as well as storage of communication log.

Article Manager – Management of article data records. Packing scheme, print layouts etc. are stored in the article data record. Each article gets its own data record.

Event Manager – Control of the Serialisation and Aggregation processes. The processes and data are connected and then forwarded to the components. This is visualised to the user.

Batch management module – management of orders, e.g. create, release, edit and delete.

■Interface

-

Visualisation client – software module to operate on a wide range of devices and terminals. QNX or Windows 7 are possible and the visualisation can be designed as required.

-

Import-export interface – interface to higher-level systems. These can communicate file-based or port-based, and various file formats and protocols can be used

-

Software interface – interfaces to various devices on the line, both for scanware systems and other components.