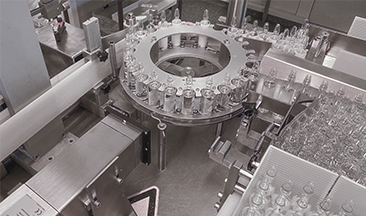

The SIGNUM ring code inspection system is used on packaging and labelling machines to exclude faulty ampoules and under-mixing of foreign preparations. The enquiries we receive regarding inspection solutions for ampoules are constantly increasing.

In addition to the inspection of ampoules in transparent PVC blisters and cardboard trays, single ampoules and mixed loads are also inspected on the lines. Both colour markings on preparations and the presence of labels can be inspected. For the inspection of labels, the lighting setting can be defined independently. Successive object illumination takes place twice in this process. Both images are evaluated in the same inspection step.

The SIGNUM ring code inspection software also makes it possible to inspect the colour rings. Different criteria of the ring code quality are taken into account, such as the number of colour rings, the ring colours, the sequence of the ring codes, the length of the entire colour ring code as well as the interruptions, widths and distances of the rings. Since this software is mostly used on labelling machines, the labels are inspected before dispensing.

On the user interface, all ring code inspection systems are operated by a uniform menu structure. This enables the user to operate each system intuitively, as the menu is self-explanatory, so that the operator does not need any previous knowledge and can start working after a short briefing.

The quality requirements are met by high-quality hardware components and the always up-to-date software versions, enabling the pharmaceutical as well as the cosmetics industry to carry out reliable quality controls.