High Resolution Inspection

Home / Our Solutions / Blister Inspection / High-Resolution Inspection

■SPECTRA HR High Resolution Product Inspection

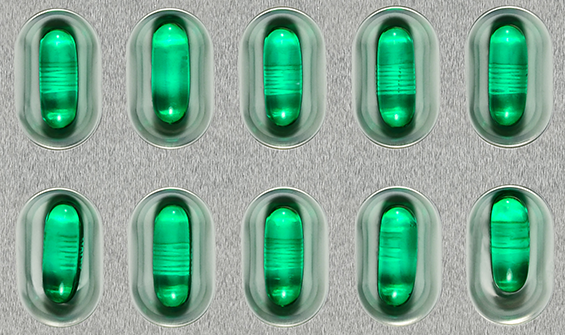

The high-resolution inspection system SPECTRA HR is used for quality control in the pharmaceutical sector. By using 3CMOS cameras, it offers outstanding colour separation performance, allowing products with difficult colour and contrast conditions to be inspected. In combination with the largest software package, it enables unique inspection parameters and functions. Also the inspection of products products with minimal differences in colour and shape in the same blister at high speed. The all-rounder for every challenge.

■Inspection Criteria and Objects

Inspection objects:

- Tablets

- Oblongs

- Dragees

- Hard and soft gelatine capsules

- Medical strips

- Sealed products

- Special forms

- Dialpack

- etc.

Examination criteria:

- Contaminants

- Colour

- Presence

- Size

- Shape

- Position

- Circumference

- Broken product

- Overfilling

- Surface defects

- Serial errors

■Advantages of High-Resolution Blister Inspection

All blister geometries and combinations of product and packaging material can be recognised

All parameters integrated in the system can be used simultaneously

The use of multi-camera systems allows the inspection of different products and shapes in the same blister

The use of the real-time operating system QNX® enables the fastest signal processing and high reliability

■Special Applications of SPECTRA High Resolution

Contraceptives

Hormone preparations are a particular challenge for inspection systems because they are usually very small and different products, often sorted by week of intake, are brought together in one blister.

Bulk Inspection

Bulk inspection is used to detect foreign products, fragments and foreign particles and their ejection. SPECTRA Bulk with high-resolution cameras is the best solution here.

Japan Quality

By using several cameras, product inspection can also be carried out under Japanese quality standards. SPECTRA HR detects even the smallest optical blemishes and finest particles.

■Software Facts of the High-Resolution Inspection

Outstanding software features, such as꞉ filling statistics and production documentation, configurable machine stops and diagnostics for colours, pocket, blister and error images, comprehensive audit trail.

The software of SPECTRA HR is equipped with improved algorithms for shape recognition. By using several cameras, different products in the same blister as well as different shapes with the smallest differences in shape can be reliably detected.

The system’s colour separation performance even detects colour differences that can barely be seen with the naked eye. Different colours in the same blister are thus reliably distinguished. No other system offers such accuracy and reliability.

Special algorithms:

X-y measurement, with which, for example, the different positions of the product are evaluated for hard-gel capsules with heterogeneous filling.

Detection of upright objects – The detection of upright objects reduces ejection as they are identified as correct instead of being ejected as too small.

Automatic mask tracking compensates for trigger timing in intermittent machines, which depends on belt speed and other technical factors.

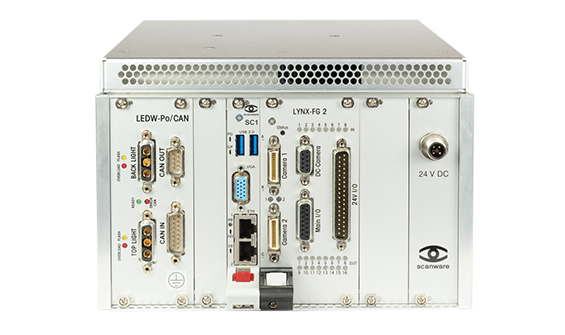

■Technical Data - Hardware

Evaluation unit

- 42 HP, 3.5 RU

- 240 GB SSD hard disk

- I/O system D-I/O 16 (standard) or TCP/IP, EtherCAT, integrated PLC (extended)

- scanware-developed frame grabber

- scanware-developed image multiplexer

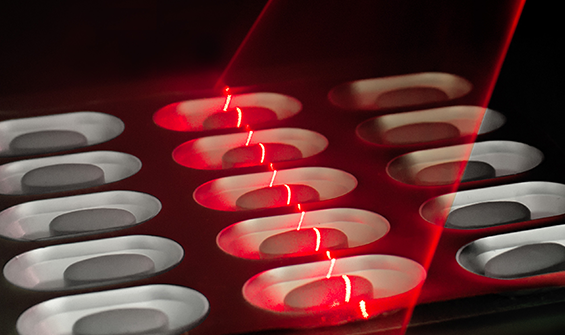

Illumination

- Designed by scanware with up to 3,000 LEDs per standardised unit

Use of SMD-W LED - Top light, back light, side light or or diffused illumination – freely combinable

- Homogeneous, reproducible and adjustable in 2 × 16 brightness levels for optimal colour measurement

Camera

- 3CMOS colour sensor

- Camera Link interface for low-interference data exchange of large amounts of data and thus longer cable lengths than USB and FireWire

- Evaluation speed: 55 fps

- Camera resolution 3× 2, 5 or 12 MPx (when using the Japan Quality, where 4 cameras are used)

- Colour resolution in 16 million colour shades

- RGB Bayer filter – colour tones are calculated by means of filters in red, green and blue based on brightness

- Powerful, non-condensing unit ideal for highest performance in continuous operation

- Built-in correction of colour errors and blur, further enhanced by scanware software algorithms

Then please use our contact form. We will get back to you as soon as possible.